PN10 DN250 Russian Standard Flange

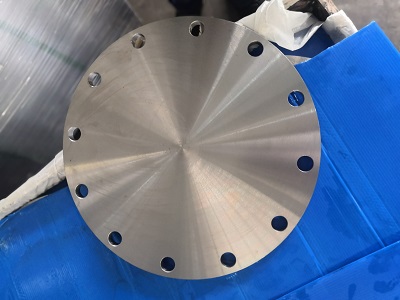

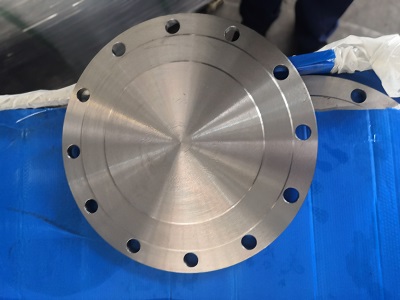

To put it simply, the blind plate is a solid flange used to close the end of the pipe.

Generally used in the feed water branch pipe end. There is a temporary part of the pipe section to first pressure test used for temporary closure.

Flanges are disk-shaped parts, most commonly used in pipeline engineering. Flanges are used in pairs.

In pipeline engineering, flange is mainly used for pipeline connection. In the need to connect the pipe, various installation of a flange, low pressure pipe can use wire flange, the use of more than 4 kg of pressure welded flange. Put a seal between the two flanges and fasten them with bolts. Flanges of different pressures have different thicknesses and use different bolts.

Water pumps and valves, when connected with pipes, the local parts of these equipment are also made into the corresponding flange shape, also known as flange connection.

All in the two planes in the periphery of the use of bolt connection at the same time closed connection parts, generally called "flange", such as the connection of ventilation pipe, this kind of parts can be called "flange class parts".

But this connection is only a part of the equipment, such as the connection of the flange and the water pump, it is not good to call the water pump "flange parts". Relatively small, such as valves, can be called "flange parts". Flange connection is an important connection mode in pipeline construction. Flange connection is the two pipes, pipe fittings or equipment, respectively fixed on a flange plate, between the two flanges, plus flange pad, bolted together to complete the connection. Some pipe fittings and equipment have their own flange, also belong to the flange connection.

PN10 DN250 Russian Standard Flange refers to a particular type of flange that is commonly used in Russia for pipelines. The term PN10 stands for "Pressure Nominal 10," which refers to the maximum allowable pressure that the flange can handle. In this case, PN10 indicates that the flange can handle a maximum pressure of 10 bar or 145 psi.

The DN250 refers to the nominal diameter of the flange, which is 250 millimeters or approximately 10 inches in diameter. The Russian standard for flanges specifies different dimensions and measurements for each type of flange based on their pressure rating and diameter.

This type of flange is typically used in medium-pressure applications where the fluid is not too corrosive or abrasive. To properly install a PN10 DN250 Russian Standard Flange, the flange should be bolted to a matching flange attached to the pipe or equipment. A gasket is usually placed between the two flanges to create a tight seal.

Like with any flange installation, it is important to follow the proper procedures and guidelines to ensure a safe and reliable connection. This includes tight bolt torque, proper alignment, and using the correct type of gasket for the specific application.

Our Company

Jin Runyuan flange of Shandong Machinery CO., LTD is located in the famous "township of the blacksmith"-Shandong Jinan chapter grave area set street agency headquarters, where convenient transportation beautiful environment. Company was founded in 2001, covers an area of 20000 square meters, is a professional manufacturer of forging flange company, main products: Japanese standard, American standard, German standard, the standard also can according to customers drawings or samples processing. Existing fixed assets of 40 million,the annual output 40 million tons.Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries and regions, such as product quality deeply the general customers the high praise and trust.

Company strong technical force, professional experience, equiptment, professional production and technical personnel 10 people, the production of 120 front-line workers, management personnel E people, packing, inspection personnel more than 20 people. High quality international most advanced forging machinery processing, assembly, inspection, packaging production lines, product quality meet the national and international standards, and has obtained ISSO9001-2000 quality management system certification, the French classification society certification, China special equipment manufacturing license, pressure vessel manufacturing license.

Our Factory

Raw Material Blanking

Laboratory Examination

Forging&Forging and Pressing

Machine Processing

Enterprise Oualification Honor